Milk Powder Drying Production Line

Description

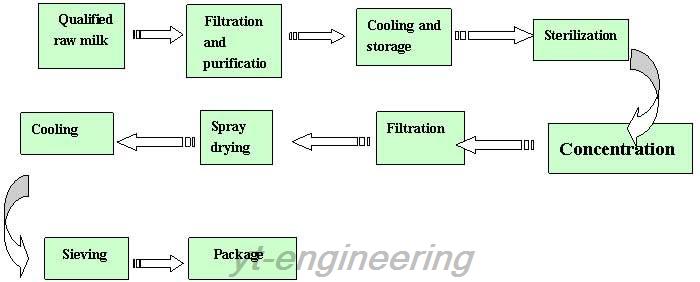

Raw milk usually consists of adipose, protein and microelements. Generally its solid content is 10.5% to 12%. Spray dryer can be used to produce whole milk powder. And the generally process is as follows: raw milk – acceptance – filter – purification – cooling – milk storage – sterilization – concentration – spraying – cooling – sieve – packing.

Features

1. Spray drying machine in food and health industry can be used to concentrate whole milk powder. This spray dryer is capable of improving the solid concentration from 10.5% to 45%.

2. The moisture content of the finished products after spray drying is about 5%.

3. With the factor that the temperature of outlet of the spray dryer is about 70℃, the cooling process is also a dehydration process. Usually this process is able to drop the water content to 2%.

4. During the cooling process, silica dispersant should be added because the whole powder is tended to absorb moisture and block together.

5. For spray dryer machine, customers are free to choose either centrifugal spray or pressure spray. The former produces powder products and the latter granule products.

Process Flows of Spray Drying Machine in Food and Health Industry

Our drying equipment includes vacuum drying machine, spray dryers, chamber dryer, tunnel dryer machine, belt dryers, flash dryer and air stream dryer. Drying technology has wide application areas. Facing numerous industries, various physical and chemical properties of materials, product quality and different requirements, the drying technology has been developed into a multi-industry and interdisciplinary technology with experimental and scientific natural.

English

English Русский

Русский 日本

日本